Nothing major needs to be moved, nothing needs serious resizing, etc. Cleveland heads require less work than any other muscle car era head. Anything more than that is not an essential. I mention all the above to clarify what "could be" essentials, and thus what tools, bits, sanding rolls, etc you'll need to get it done. Monty, you mentioned doing the "essentials" but that left more questions in my mind than anything else. They don't need to be matched, the head's port inlets should be bigger than the manifold runners, so there's no ridges in the air stream. Match the head's port inlets to a gasket, just clean up the intake manifold runners if needed. Once its pressed-in it should be sized with a 0.3430 reamer. It should be shortened to 1.625" insertion length (length below the flange). VG-7501R is a universal guide that is almost exactly what is needed for the 351C, except its too long (assuming the valve stems are 0.3415 OD). The guide within the valve pocket will require a burr to knock it down. The upper part of the guide, in the middle of the spring seat, can be knocked down with a fly cutter. Its common these days to completely remove the cast-in guides and press-in the exposed style of guides.

I perform the spring seat work and rocker arm pedestal work (if any) afterwards. Once the seats are ground that establishes the valve heights. But I always perform the valve guide work and pocket and combustion chamber blending work before I hand the head castings over to the seat grinder. I've always relied on others to perform the valve seat jobs, I've never owned valve seat grinding or cutting equip. They are 1.75 off the shelf, and 1.90 is about the max you can take them. Its very easy to open up the throat of the 2.19" intake pockets too far, and ruin the venturi. Roughly 0.3 inches less than the OD of the valve head, this applies to both intake and exhaust.

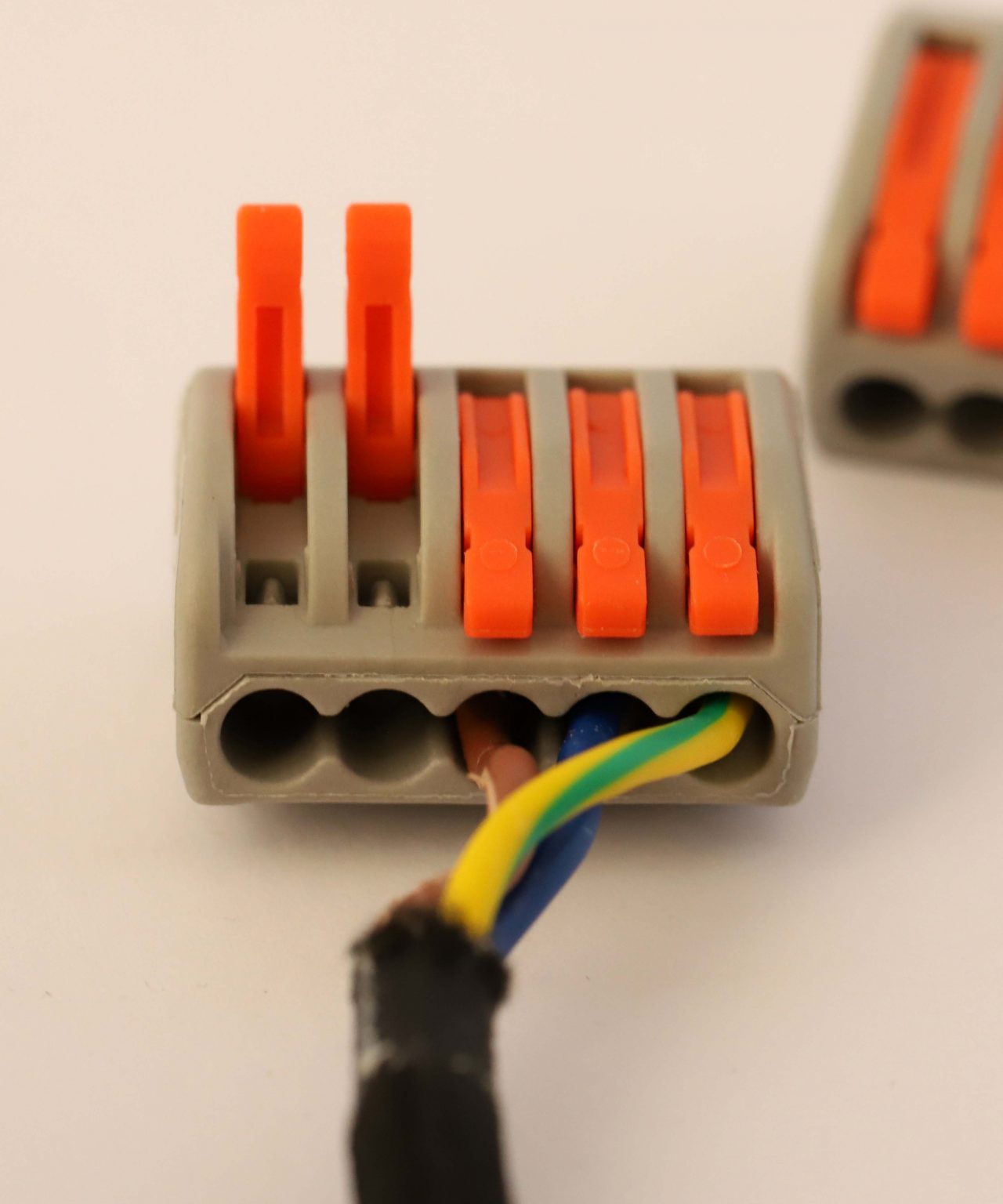

Electric porting kit plus#

You need room for a 0.060 wide intake seat, or a 0.080 wide exhaust seat, plus the 30 and 60 degree angles on either side of the seat. Street engine throats should be 85% of the valve head OD max, or enough to get the sonic choke above red line as a minimum. For a Pantera the flat roof in the exhaust valve pockets and the bump in the exhaust port roof can be eliminated. Of course sharp edges, ridges, etc should be removed everywhere. These days I lean towards only profiling the portions of the valve pockets and combustions chambers into and out of the valve seats, and sizing the valve throats.

0 kommentar(er)

0 kommentar(er)